Technological advancements are fundamentally transforming how electricians manage electrical panel issues. By integrating sophisticated diagnostic tools and smart solutions, professionals can now identify problems more efficiently. Devices such as thermal imaging cameras and smart multimeters provide real-time insights into system conditions. This evolution raises questions about the implications for repair practices and preventative strategies. What does this mean for the future of electrical system maintenance and reliability?

Key Takeaways

- Advanced diagnostic tools, like digital multimeters, enhance accuracy in identifying circuit overloads and loose connections in electrical panels.

- Thermal imaging cameras detect overheating components, allowing electricians to address potential failures before they escalate into serious hazards.

- Smart multimeters with wireless connectivity streamline troubleshooting, improving efficiency in diagnosing electrical flow irregularities.

- IoT-enabled smart panels facilitate real-time monitoring and diagnostics, enabling proactive management of electrical systems to prevent issues.

- Machine learning algorithms support predictive maintenance, minimizing downtime and enhancing the reliability of electrical panel performance.

Understanding Common Electrical Panel Problems and Their Impact

While many homeowners may overlook their electrical panels, understanding common electrical panel problems and their impact is essential for ensuring safety and efficiency in residential and commercial buildings. Issues such as circuit overloads, loose connections, and outdated panels can lead to significant hazards, including electrical fires and property damage. Circuit overloads occur when too many devices draw power simultaneously, risking tripped breakers or overheating. Loose connections may cause arcing, posing a fire threat. Moreover, outdated panels may not accommodate modern electrical demands, leading to inefficiencies. Recognizing these problems allows property owners to prioritize maintenance, ensuring their electrical systems operate safely. Addressing common electrical panel issues not only enhances safety but also contributes to the longevity of the electrical infrastructure.

The Role of Technology in Diagnosing Electrical Panel Issues

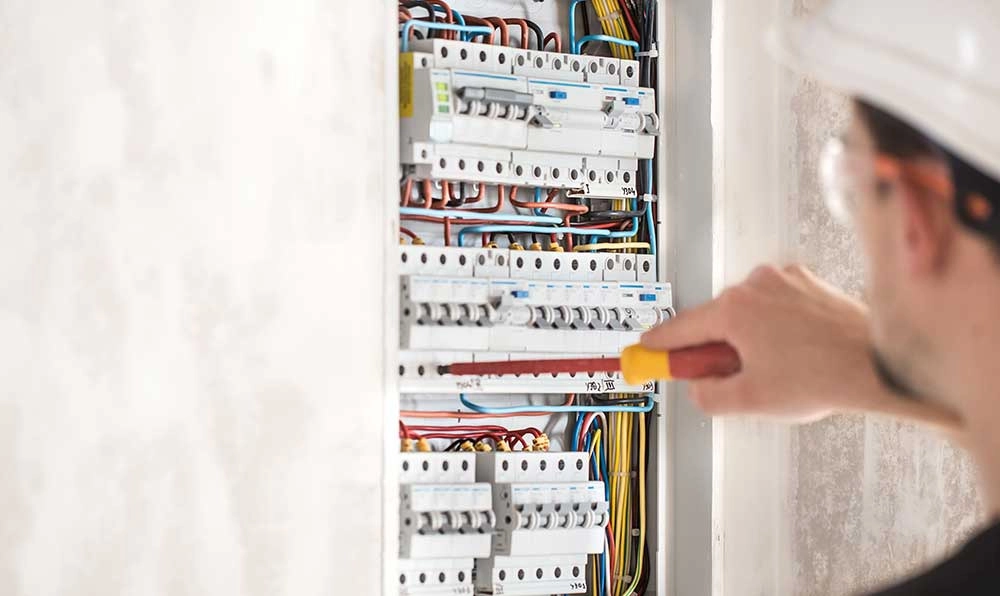

How can technology enhance the diagnosis of electrical panel issues? Advanced diagnostic tools have revolutionized how electricians identify common electrical panel problems. Utilizing software applications and digital multimeters, professionals can analyze voltage levels, current flow, and system integrity with unprecedented accuracy. Infrared cameras allow for thermal imaging, revealing hotspots that indicate potential failures. Additionally, data logging devices track historical performance, enabling electricians to identify recurring issues and predict future malfunctions. By integrating these technologies, electricians can diagnose problems more efficiently, reducing downtime and ensuring safety. This approach not only fosters a sense of community among professionals who share insights and solutions but also enhances overall service quality, benefiting both electricians and their clients in addressing common electrical panel issues.

Innovative Tools for Repairing Common Electrical Panel Problems

The integration of advanced diagnostic tools has paved the way for innovative repair solutions to address common electrical panel problems. Among these tools, thermal imaging cameras stand out, enabling electricians to identify overheating components and potential failures before they escalate. Additionally, circuit analysis devices provide real-time monitoring, allowing for the detection of irregularities in electrical flow. Smart multimeters, equipped with wireless connectivity, facilitate data sharing and analysis, enhancing troubleshooting efficiency. Moreover, specialized software applications streamline inventory management of replacement parts, ensuring that electricians have the necessary components on hand. Collectively, these innovations not only improve the accuracy and speed of repairs but also foster a collaborative environment among electricians, strengthening their capacity to resolve common electrical panel issues effectively.

Preventative Measures to Avoid Common Electrical Panel Problems

To prevent common electrical panel problems, electricians must implement a series of proactive measures aimed at maintaining the integrity and functionality of electrical systems. These measures not only enhance safety but also prolong the lifespan of electrical components. Key preventative strategies include:

- Regular Inspections: Conduct routine checks to identify wear or corrosion in electrical panels.

- Tightening Connections: Make certain all connections are secure to prevent arcing and overheating.

- Upgrading Components: Replace outdated circuit breakers and fuses with modern, reliable alternatives.

- Proper Load Management: Distribute electrical loads evenly to avoid overloading any single circuit.

Future Trends in Electrical Panel Technology Solutions

As advancements in technology continue to reshape the electrical industry, future trends in electrical panel technology solutions are poised to address common electrical panel problems more effectively than ever before. Innovations such as smart panels with integrated IoT capabilities will enable real-time monitoring and diagnostics, allowing electricians to identify issues before they escalate. Additionally, the incorporation of machine learning algorithms will enhance predictive maintenance, reducing downtime and improving efficiency. Moreover, advancements in materials science are leading to panels that are not only more durable but also energy-efficient, aligning with sustainability goals. These trends signify a shift towards proactive management of electrical systems, fostering a sense of community among electricians who can rely on cutting-edge tools to enhance their service delivery and customer satisfaction.

Frequently Asked Questions

How Often Should Electrical Panels Be Inspected for Issues?

Electrical panels should be inspected at least once every three to five years. Regular inspections help identify common electrical panel problems, ensuring safety, compliance, and operational efficiency, ultimately protecting both property and occupants from potential hazards.

What Are Signs of Overheating in an Electrical Panel?

Signs of overheating in an electrical panel include discolored breakers, a burning smell, melting insulation, or warm surfaces. Regular inspections can help identify these issues early, preventing potential hazards and ensuring safe electrical system operation.

Can I Upgrade My Electrical Panel Myself?

Upgrading an electrical panel typically requires professional expertise due to safety regulations and code compliance. DIY attempts can lead to hazards. Hence, it is advisable for homeowners to consult a licensed electrician for such upgrades.

How Long Do Electrical Panels Typically Last?

Electrical panels typically last between 20 to 30 years, depending on usage, environmental factors, and maintenance. Regular inspections can identify potential issues, ensuring safety and longevity for these essential components of electrical systems.

What Should I Do if My Breaker Keeps Tripping?

When a breaker continuously trips, it indicates an overload or fault. The individual should first reduce electrical load, then inspect for faulty wiring or devices. If issues persist, consulting a licensed electrician is advisable for safety.

Conclusion

To sum up, the integration of technological innovations is transforming how electricians address common electrical panel issues. Advanced diagnostic tools, such as thermal imaging cameras and smart multimeters, enhance the accuracy and speed of repairs while bolstering safety and reliability. Additionally, software applications streamline inventory management and predictive maintenance, enabling proactive measures against potential failures. As these technologies continue to evolve, they promise to further revolutionize the electrical industry, ensuring more efficient and effective solutions for common panel problems.

You May Also Like To Read: